Thursday, December 25, 2008

Elektrical Chain Hoist

High quality safety chain

High tensile round steel chain, galvanized, quality group 8 High Safety

All electrical chain hoists with GS mark and CE mark

Patented safety clutch-brake system

Lifting height limitation and overload protection by safety clutch, electric limit switches also available

Asbestos-free clutch lining

Each LIFTKET is tested at the manufacturer's test stand with overload and certified. Advantages in the electrical field

Direct control or optional 24 V - low voltage control

Reliable protective system IP54

High duty cycle (up to 60 %)

Isolation class F

Tropical proof T II

220/380 V three - phase current or special voltages of 415V, 440V, 500V

Contactors and switchboards with hight quality contacts

High tensile round steel chain, galvanized, quality group 8 High Safety

All electrical chain hoists with GS mark and CE mark

Patented safety clutch-brake system

Lifting height limitation and overload protection by safety clutch, electric limit switches also available

Asbestos-free clutch lining

Each LIFTKET is tested at the manufacturer's test stand with overload and certified. Advantages in the electrical field

Direct control or optional 24 V - low voltage control

Reliable protective system IP54

High duty cycle (up to 60 %)

Isolation class F

Tropical proof T II

220/380 V three - phase current or special voltages of 415V, 440V, 500V

Contactors and switchboards with hight quality contacts

Liftket Electrical Chain Hoists

Lifting Capacity 125 – 12500 kg.

For use in industry, agriculture, craft and all fields where loads are transported.

One or two lifting speeds

Stationary version with suspension eye or hook suspenions

Movable with manual or powered travel gear

Protected against dust and splashing water

Silent run by

Diagonally interlocked gear wheels with anti-friction bearings

Precision sprocked wheel

Exact chain guide

Special Versions

Use in

Cuntruction

Merchant shipping

Medical fields

Regions with tropical climate

Entertainment industry

Storaging

High Quality

Very low headroom for use in low rooms.

Gear wheel and pinion are made from high - quality steel of extreme surface hardness.

Cranes

Crane Systems

Portable Cranes,

Monorail Cranes,

Ceiling Mounted Cranes

Console mounted monorail cranes.

Features of our standard systems are

Modularity

Quick and easy installation

Can be used NPI and C cranes

Easy and Safety Use

www.natsu.com.tr

Jib Cranes

Chemical Industry

In chemical industry, it is widely used in carrying, stacking loading, unloading and transporting the material such as the packages of raw material / semi – product/ product, barrels, boxes, bags etc. Besides our standard machines, we also produce automatic and semi-automatic custom-made apparatus and environment. They increase your productivity and save your time.

In chemical industry, it is widely used in carrying, stacking loading, unloading and transporting the material such as the packages of raw material / semi – product/ product, barrels, boxes, bags etc. Besides our standard machines, we also produce automatic and semi-automatic custom-made apparatus and environment. They increase your productivity and save your time.www.natsu.com.tr

Household Appliance

In transporting household appliances or in production and assembly lines, we offer automatic or semi-automatic custom-made projects. At the point of quality control and packing, ergonomic solutions offered that enable to carry the product securely. It is commonly used in carrying or stacking the packages.

In transporting household appliances or in production and assembly lines, we offer automatic or semi-automatic custom-made projects. At the point of quality control and packing, ergonomic solutions offered that enable to carry the product securely. It is commonly used in carrying or stacking the packages.www.natsu.com.tr

Automotive Industry

Partner

Natsu Partner is the best friend of your operator. It allows your operators to lift, transport, rotate and load any objects effortlessly and increases the productivity. Due to its mobility feature, it is suitable for indoor and outdoor uses. Natsu Partner is suitable for handling.

Natsu Partner is the best friend of your operator. It allows your operators to lift, transport, rotate and load any objects effortlessly and increases the productivity. Due to its mobility feature, it is suitable for indoor and outdoor uses. Natsu Partner is suitable for handling.Glass, plastic and sheet metals,

Cardboard boxes,

Cement bags,

Rolled materials,

Wood panels and wooden products,

Stones,

Furniture,

Household appliances etc.,

FEATURES

Easy to use,

Wide range of movement,

Lifting height is 2.40 m. from the floor,

Ergonomic design,

Enables you to carry the products securely.

Easy to use,

Wide range of movement,

Lifting height is 2.40 m. from the floor,

Ergonomic design,

Enables you to carry the products securely.

Carrying Systems With Manuel Vacuum Apparatus

Automatic Loading and Unloading Systems

Glass Carrying Systems with Manual Vacuum Apparatus

VCM 200 / 300 / 500 / 750 Models Model Vacuum Glass VCM is equipment used to carry the glasses in wide dimensions. It can be fixed on a roller-crane or on a jib crane. This machine is usually used in;

Burring machine lines,

Double glass production lines,

Vertical washing lines. VCM-T / 250-500 ModelsVCM-RT 250/500 is very helpful to make the job easier for turning and rotating the big sized glasses.

Burring machine lines,

Double glass production lines,

Vertical washing lines. VCM-T / 250-500 ModelsVCM-RT 250/500 is very helpful to make the job easier for turning and rotating the big sized glasses.

Automatic Glass Loading - Unloading Systems

Automatic glass loading machine takes the glasses from the pallets and feeds the rodaj machine.

Automatic glass loading machine takes the glasses from the pallets and feeds the rodaj machine.The glasses which are in upright position (1, 2 or 3 rows), are placed in front of the automatic loading robot by a forklift. The operator enters the glass height into the control panel and starts up the system. Automatic glass loading machine takes the glasses from the pallet and releases them on he conveyor. The motorized conveyor works on 2 axes. After positioning the glass on the x-axis, the glass goes through y-axis to the rodaj machine. The entire process takes only 12 seconds.

Sheet Metal Carrying with Manual Vacuum Apparatus

Vacuum sac is a lifting device for transporting metal sheets of up to 600-1000 mm - 3000- 12000 mm sizes. Its flexibility and versatility allows you to lift and handle different sized and height of work pieces.

Vacuum sac is a lifting device for transporting metal sheets of up to 600-1000 mm - 3000- 12000 mm sizes. Its flexibility and versatility allows you to lift and handle different sized and height of work pieces.Adjustable suction feet longitudinal and transversal.

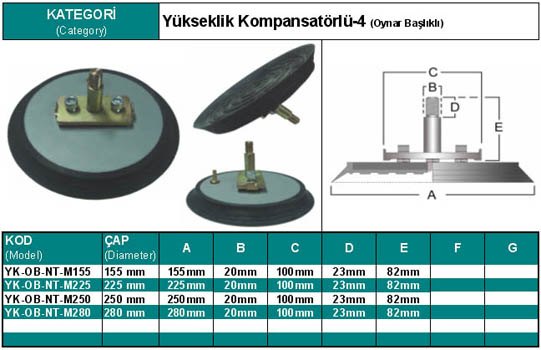

Suction pads with height compensator.

Safety and easy to operate due to the ergonomic design.

Apparent vacuum meter

Vacuum relief cup

Non-return valve

Overload relay for motor.

Vacuum control with manual valve

Adjustable suction pads for unusual surfaces

Danger indicator

During power failure or vacuum failure the sound and light signal systems

Suction pads with height compensator.

Safety and easy to operate due to the ergonomic design.

Apparent vacuum meter

Vacuum relief cup

Non-return valve

Overload relay for motor.

Vacuum control with manual valve

Adjustable suction pads for unusual surfaces

Danger indicator

During power failure or vacuum failure the sound and light signal systems

Automatic-Semi Automatic Sheet Metal Loading and Unlaoding Systems

Natsu machine has standard and custom-made solutions for the companies, which need sheet metal handling system by using Vacuum Technic. Automatic and semi automatic Sheet Metal Loading and Unloading system has been designed for the standard type, also customer requirements. Our machines offer solutions for your following processes and systems.

Natsu machine has standard and custom-made solutions for the companies, which need sheet metal handling system by using Vacuum Technic. Automatic and semi automatic Sheet Metal Loading and Unloading system has been designed for the standard type, also customer requirements. Our machines offer solutions for your following processes and systems.Laser cutting machines.

Punching machines.

Bending Machines .

Sheet Metal Searing Systems.Our production range provides you to increase efficiency and safety for your handling and feeding processes for sheet metals.

Decreases process lead time,

Increases efficiency and productivity

Reduces the operative risk, increase safety.

Reduces process cost.

Gentle transportation of the work piece.

Easy integration to production process.

VAKUMER 500-700

Vakumer is manufactured for lifting big pieces of marble, granite and travertine slabs or strips with vacuum technology. The system works with vacuum pump or ejection. Vacumer 500 can be mounted on a Jip Crane or X-Y bridge Crane. The turning system is optional such as pneumatic, hydraulic or mechanic.

Vakumer is manufactured for lifting big pieces of marble, granite and travertine slabs or strips with vacuum technology. The system works with vacuum pump or ejection. Vacumer 500 can be mounted on a Jip Crane or X-Y bridge Crane. The turning system is optional such as pneumatic, hydraulic or mechanic.Easy to operate due to the ergonomic design

Suction pads for handling different materials

Safety and productivity

Durable drive units

The ideal method for holding and lifting without damage to workpiece

Apparent vacuum control

Suction pads with height compensator

COMBO Models

VAKUMER 250

Designed for handling and transporting marble / granite travertine strips. The vacuum system has vacuum pump and vacuum ejector options and the turning mechanism in pneumatic. It works with jib crane and has a wide range of suction cup options enabling you to carry even cracked or broken pieces. ADVANTAGES

Designed for handling and transporting marble / granite travertine strips. The vacuum system has vacuum pump and vacuum ejector options and the turning mechanism in pneumatic. It works with jib crane and has a wide range of suction cup options enabling you to carry even cracked or broken pieces. ADVANTAGESIncreases the productivity (less time needed to carry the material)

Saves your time and labor costs

Less broken slabs due to carrying.

Easy to use

Safety (minimizes the risk in injuries or damages)

Functional design depending on the material.

Automatic Loading-Unloading Machine For Strips

Automatic strip loading/unloading machines are especially used to load/unload the strips to the splitting machines, disc cutters or polishing lines. The strips which are lined up in vertical/horizontal position on the pallets are placed in front of the automatic loading machines by a forklift after cutting by the block cutters. The operator enters the position of the material (vertical/ horizontal) and starts up the machine.Automatic strip loading machine takes the strips from the pallets in order and releases them on the conveyor horizontally. The conveyor automatically feeds the second strip to the machine after the first one. In the meanwhile, the automatic strip loading machine brings the next strip to the conveyor and releases it if the previously fed strip is done.

Automatic strip loading/unloading machines are especially used to load/unload the strips to the splitting machines, disc cutters or polishing lines. The strips which are lined up in vertical/horizontal position on the pallets are placed in front of the automatic loading machines by a forklift after cutting by the block cutters. The operator enters the position of the material (vertical/ horizontal) and starts up the machine.Automatic strip loading machine takes the strips from the pallets in order and releases them on the conveyor horizontally. The conveyor automatically feeds the second strip to the machine after the first one. In the meanwhile, the automatic strip loading machine brings the next strip to the conveyor and releases it if the previously fed strip is done.Natsu Vacuum Lifting System

- NATSU Machine, with its accumulated knowledge and experience in vacuum systems, shares today’s modern technology with you. Its fast and reliable working principles, quality and a great variety of products make NATSU an indisputable brand. Our reputation is one of reliability, promptness, and competitively, with a demonstrated willingness to accept any challenge

- When you contact us, we elaborately evaluate all the combinations of vacuum lifting and carrying systems to meet your needs and definitely come up with a safe, economical and satisfactory solution. In a time when customer service and superior products are of primary importance to one's success, NATSU Machine has the experience to exceed all of your expectations and requirements

We are always at your disposal with our unlimited spare parts and post-sale services.

www.natsu.com.tr

- When you contact us, we elaborately evaluate all the combinations of vacuum lifting and carrying systems to meet your needs and definitely come up with a safe, economical and satisfactory solution. In a time when customer service and superior products are of primary importance to one's success, NATSU Machine has the experience to exceed all of your expectations and requirements

We are always at your disposal with our unlimited spare parts and post-sale services.

www.natsu.com.tr

Subscribe to:

Comments (Atom)